Tablet coating is an important process step in pharmaceutical production. Coatings can fulfil many functions: Sometimes they serve to protect the product, other times they are used to change the colour or mask taste; sometimes they also facilitate modified drug release. Often different functions are combined.

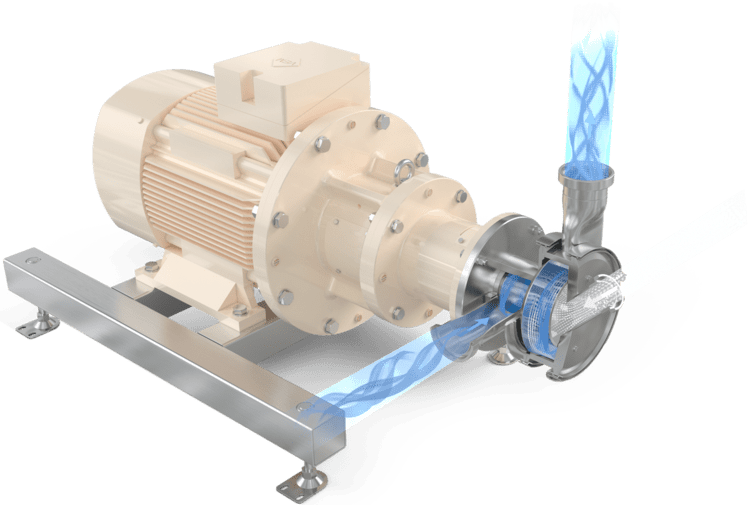

Process plant for tablet coating production

- Industry:

- Pharmaceutical industry

- End product:

Tablet coating

- Application:

Induction, wetting and dispersion of pigments, fillers and thickeners in ultrapure water

The customer requirements:

- Batch size: 450 L

- Space requirement: 3.3 x 1.6 x 2.7 m

- Degree of automation: Very high

- Powder feed: Direct from the supply container

- Cleanability: Automated

- Fluid addition Automatic

Advantages compared to the previous process:

Compared to conventional methods for producing the tablet coatings, the use of ystral Conti-TDS technology in conjunction with a complete system designed by ystral, opens up a wealth of new possibilities. It was possible to perfectly coordinate the Conti-TDS with adjacent processes and drastically reduce process times.

- The system is extremely flexible. All solvent-based and aqueous coating suspensions can be prepared.

- The powder can be inducted either via a induction lance or directly from the container.

- Liquids are inducted directly. Droplet sizes in emulsions prepared in this way are in the nanometre range.

- The service life of the filter installed before the coater increases tenfold.

- Energy consumption has reduced by about 60 % over the previous process.

- Product quality has improved significantly. Suspensions remain homogeneous and stable over the long-term.

- The new process plant allows production time to be reduced by up to 80 %. In certain cases, it was possible to reduce production time from eight hours to just one.

- Storage stability has increased by up to 90 %. This allows a hopper agitator to omitted during the coating process.

- A vacuum is generated in the mixing chamber. The powder is added without dust formation and loss-free.

- The new process plant can also easily process difficult powders that, for example, are difficult to wet, swell spontaneously, foam heavily or clump together.

- Colloidal wetting and dispersion is performed under vacuum. The raw materials are completely de-agglomerated.

- The manufacturing process is 100 % reproducible.

- The cleaning process for the paint preparation container runs automatically, while the next paint suspension is already being prepared in parallel.

- The system is linked to the automatic generation of manipulation-proof electronic logs and documents.