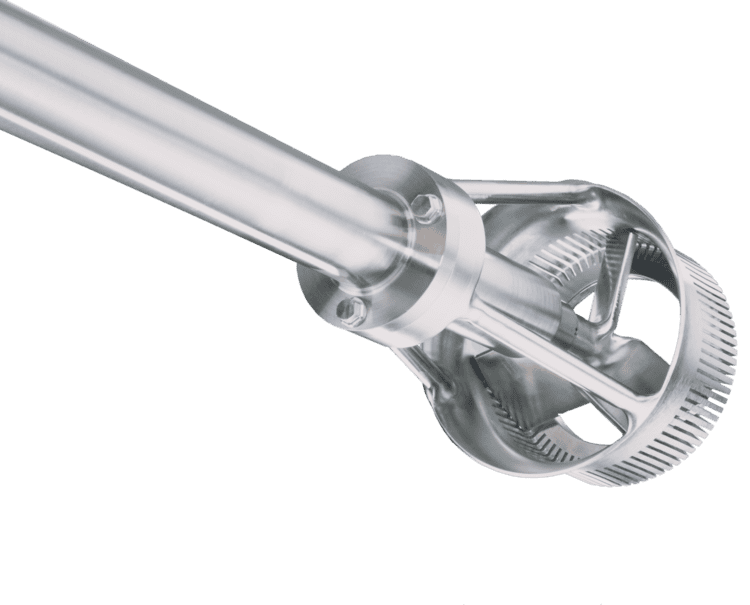

YSTRAL Dispermix

Mixing and dispersing in a single operation

The YSTRAL Dispermix is used when the powder/liquid-to-liquid mixing is insufficient and a shear ring dispersion is too intense. The Dispermix subjects the container contents to vertical intensive mixing in the micro and macro range whilst dispersing the product in the same operation. Additional downstream sheer-ring dispersion is omitted.

With its optimal mixing/ dispersion performance, higher economic potential and easy-to-use mixing tools, the Dispermix meets the demanding requirements of high-end production processes to induct liquids or powders into liquid.