Sodium lauryl ether sulphate, short: SLES, is the basis of many hygiene products such as liquid soaps and shampoos. It is manufactured as a 70-percent good, which for production has to be diluted with water to 5 to 28 percent. However, this dilution is not so easy. If product in batches is not desired, we recommend a continuous, quantity-proportional dilution.

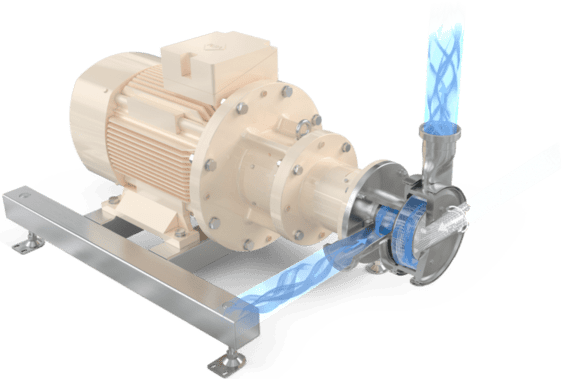

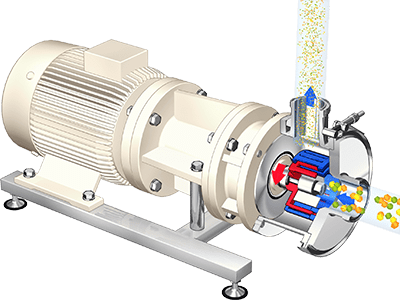

With the KEMA, the SLES can be mixed directly from the tanker without first having to be fed into a raw material storage tank. This saves space and time. The SLES is mixed and diluted with water directly in an inline dispersion machine. The two phases are only mixed together and dispersed in the shearing phase. This is important for the quality of the end product.