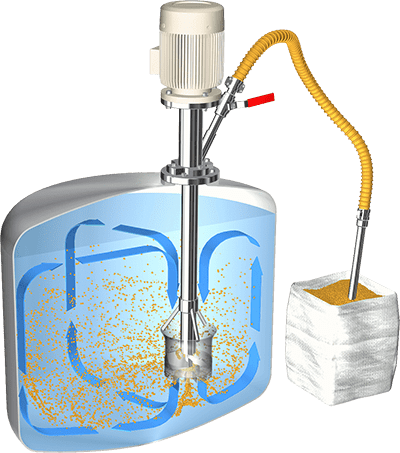

YSTRAL TDS-Induction Mixer

Low-dust induction, suspension and dissolution of powders in liquids

TDS Induction Mixers draw powder, liquids or gases below their level into liquids and at the same time homogenise the contents of the container.<br/> The vacuum required for induction is generated in the mixing head.<br/> The machine is installed in the container from above by means of a flange or traverse. Alternatively, the TDS Induction Mixer can work on a lifting frame.