YSTRAL Multipurpose

Multifunctional thanks to exchangeable shafts and tools

Flexibility is one of the most important requirements today. Production must be able to manufacture a large number of product variants and also newly developed products in an order- and application-oriented manner. To ensure this, multipurpose machines were developed for mixing tasks.

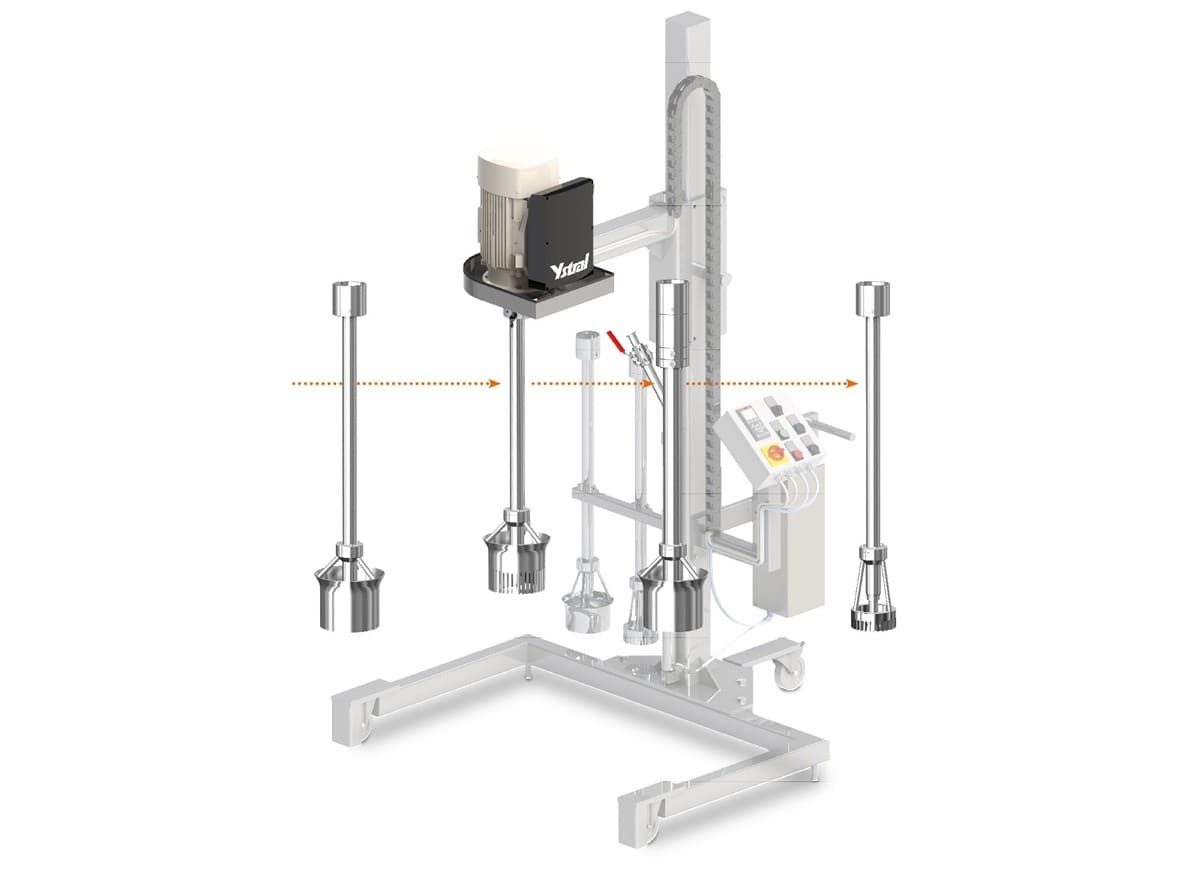

The modular design of the multipurpose units, i.e. exchangeable tool shafts and/or interchangeable mixing and dispersing tools, is only common within the laboratory environment.

The YSTRAL Multipurpose offers flexibility in chemical, food, cosmetic and pharmaceutical production. Different products and product quantities can be manufactured using a single machine and the most suitable tool.

To meet the clean room and pharmaceutical sector requirements, all connections are sealed in accordance with GMP guidelines. Numerous versions with different drive and lifting column combinations add to the versatility of the multipurpose systems.